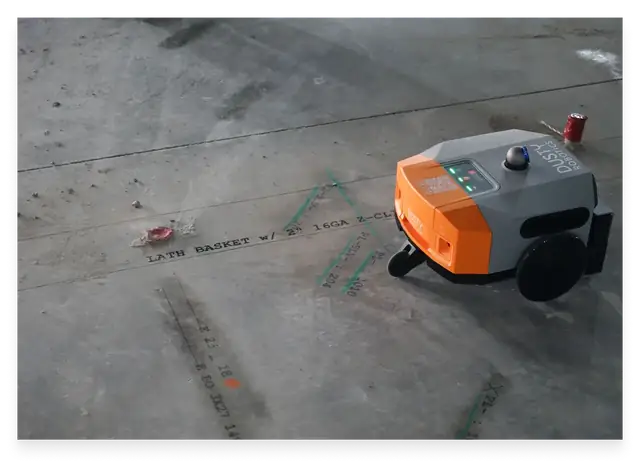

SitePrint

Autonomous layout robot

Availability: Market Ready

Known Customers

Key Highlights

Delivers up to 10x faster layout productivity by autonomously printing lines, text, arcs, and floor-deviation data.

Achieves ±2 mm layout accuracy with optimized RTS alignment for high-precision MEP and interior wall layout.

Prints up to 1,260 meters per hour, covering large slab layouts in a single shift.

Navigates between layout segments at 2.52 km per hour for continuous autonomous workflow.

Case Studies

FL Crane & Sons achieve 61% cost reduction and 8× faster layout using HP SitePrint for 84,468 ft² hospital interior project.

- 61% cost reduction ($52,229 → $20,478)

- 8× faster layout (348 hours → 44 hours)

- 304 labor hours saved

Valley Interior Systems achieves 10× faster wall layout and 1-operator workflow with HP SitePrint across 18 projects.

- 10× productivity increase (30 → 300 ft/h)

- Saved 3,826 labor hours (4,228 → 402)

- $70K total cost savings across 18 projects

ICI achieves 8× productivity and 4× faster layout with HP SitePrint on 60,000 ft² project.

- 8× productivity increase (60 → 220 ft/h)

- 78 labor hours saved per project

- 2% total cost reduction ($16,250 → $15,913)

Betonmast Buskerud-Vestfold achieves 8× higher productivity and 15% cost savings using HP SitePrint for multi-trade layouts.

- 8× productivity improvement in marking operations

- 4× faster layout speed (29 → 112 m²/h)

- 15% total cost reduction (131,920 → 112,013 NOK)

Hoar Construction achieves 3× faster MEP layout, 18% cost reduction, and 1/8” precision with HP SitePrint.

- 3× faster layout (40 → 120 points/hour)

- 1/8” precision accuracy

- 18% total cost reduction ($7,369 → $6,065)

Brandt achieves 5× faster layout and major cost savings using HP SitePrint’s pay-per-use model at Temple Data Center.

- 5× faster layout (28 h → 5 h)

- 6× productivity gain (40 → 230 points/hour)

- 23 hours saved on project schedule