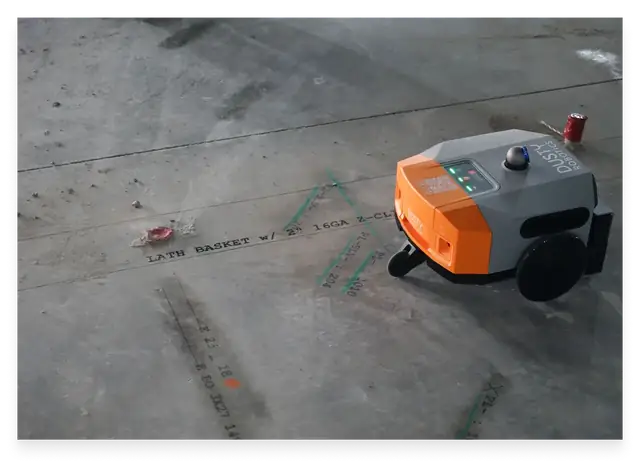

Mark1

Autonomous layout robot

Availability: Market Ready

Known Customers

Key Highlights

Delivers < 1/8 inch accuracy for intricate geometry, specialty flooring, and complex curves.

5.5-inch printhead enables all trades to be laid out in a single pass, compressing multi-week layout into days.

Operates using passive target networks with no robotic total station required, improving setup speed and layout flexibility.

Holonomic drive system enables smooth motion and precise replication of curves, arcs, and angled geometry.

Case Studies

Rugged Robotics saves 750+ hours and enables 15% faster framing for Hensel Phelps at a hyperscale data center.

- 750+ layout labor hours saved and reallocated

- 15%+ faster framing installation

- 100% verified slab penetration accuracy

Brogoitti Construction cuts layout time by 75% and saves six weeks using Rugged Robotics for precision equipment installation.

- 75% faster layout (8 weeks → 2 weeks)

- 50% reduction in layout costs

- 6-week schedule gain

Suffolk Construction cuts layout time by 60% per floor and reduces rework by 75% with Rugged Robotics’ coordinated multi-trade layout.

- 60% reduction in layout time per floor (7–8 days → 3 days)

- 75% reduction in downstream rework

- High-fidelity BIM-to-field translation

Turner Construction accelerates complex hospital renovation with Rugged Robotics’ multi-trade layout system.

- Complete critical layout within one week of mobilization

- Full trade alignment to unified building control reference

- Eliminated 2-inch misalignment risk from legacy columns

Roman Mosaic saves a week and eliminates 500 plywood sheets using Rugged Robotics for curved terrazzo flooring layout.

- 1 week saved (20% faster project delivery)

- 500 plywood sheets eliminated

- 15 labor days reallocated to installation tasks